Parker Nitrogen Membrane Modules

Description

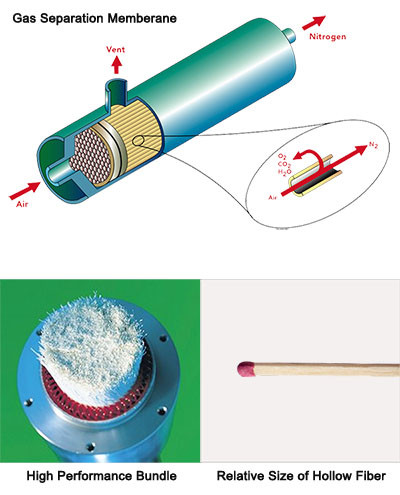

Parker Hollow Fiber Membrane Modules efficiently generate nitrogen gas from compressed air, offering a reliable alternative to traditional gas cylinders or liquid nitrogen supply. This clean, dry inert gas is widely used for oxygen removal in products and processes.

Parker memberane modules can be integrated into custom nitrogen generators or directly connected to production lines, delivering instant and continuous nitrogen supply.

Applications span various industries, including food & beverage, pharmaceuticals, chemicals, electronics, and oil & gas.

Advantages

• Less membrane modules are required - Compared to any other similar products, Parker Hollow Fiber produces more nitrogen per unit.

• Lower pressure - Parker membrane supports as low as 4 barg clean air to produce nitrogen gas.

• Energy saving - Lower pressure requires less energy.

• Environmental friendly - No heater required to open polymer membrane structure, thus reducing greenhouse gas emission.

• Robust fibre - Most tolerant fibre to particle contamination.

• Large membrane diameter - Lowest pressure drop.

• Durable engineering plastics - Average Lifespan of Over 10 Years

• Membrane ageing treatment pre-delivery - No performance decrease over time due to fibre ageing.

• Instant start-up - No time needed to heat-up

• Flexible mounting arrangements - Parker nitrogen membrane moduals can be mounted horizontally or vertically.

• Lowest noise operation - Radiated noise generated by membrane technology is extremely low.

• Maintenance free - Completely zerp user serviceable parts, saving your time and costs.

• Small footprint - Less modules are needed to produce required volume nitrogen gas.

* Above selection criteria are based on 97% purity @ 7 barg working condition, please refer to the product literature in the support section for additional performance conditions.

4 results

ViewShowcase

HiFluxx ST608 membrane modules for producing nitrogen gas at pressures up to 12 barg from a standard compressed air supply and provides nitrogen gas of 95% to 99,5% equivalent nitrogen purity.

HiFluxx DT604 hollow-fibre Nitrogen membrane modules produce nitrogen gas from compressed air to offer a cost-effective, real time nitrogen supply.

The Parker SmartFluxx SA1508 nitrogen membrane produces nitrogen gas from clean compressed air. Install the hollow-fibre membrane module into a custom-made nitrogen generator or integrate it with your production process.

Nitrogen is used as a clean, dry, inert gas primarily for removing oxygen from products and/or processes. Parker modules can be built into a custom-made nitrogen generator or can be integrated with your (production) process to provide an on-demand, continuous source of nitrogen gas.

Applications & Project Cases

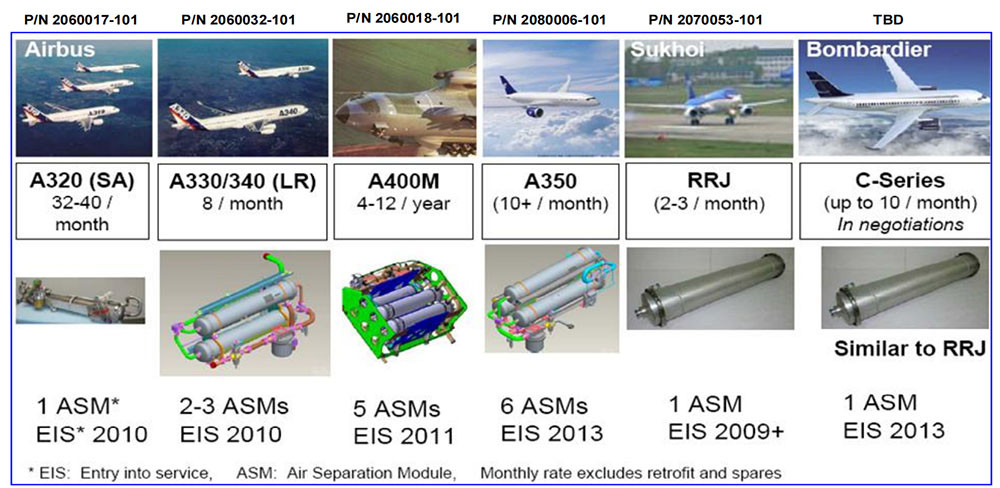

Parker membrane modules are globally utilized across industries such as aerospace, petrochemicals, marine, mining, military, and laboratories.

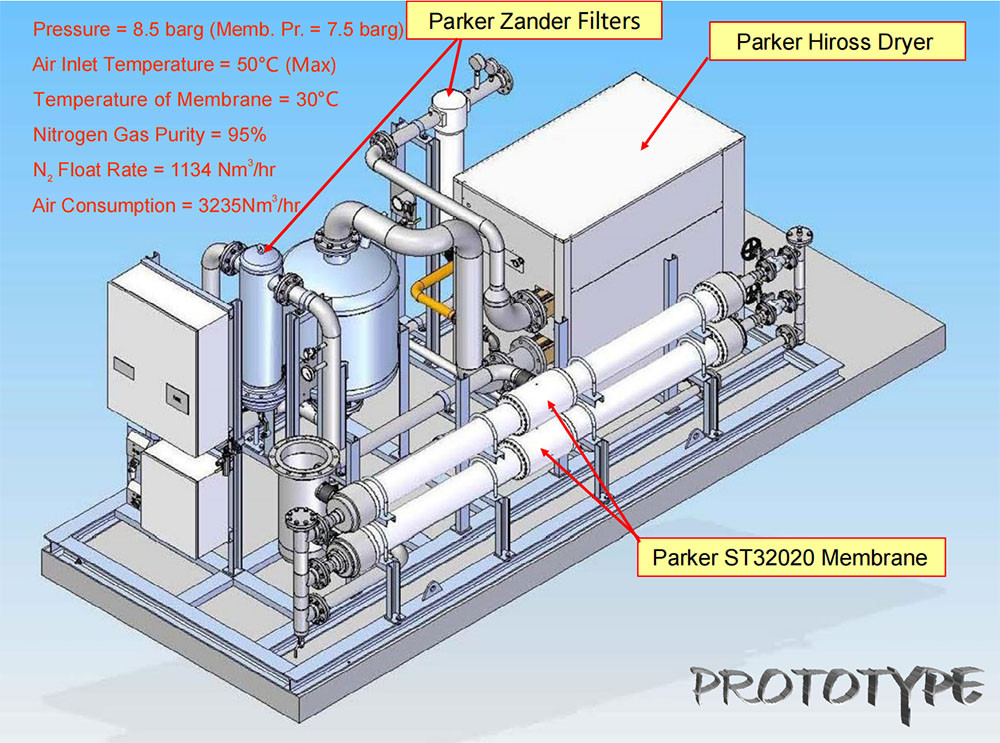

Prototype of Nitrogen Membrane

To get a complete working system you need a pressurised air system or a stand-alone compressor of prescribed capacity and a system where the membranes are built in. Ambient air is compressed and then led through the nitrogen membrane modules. The separated oxygen enriched air stream is collected at atmospheric pressure and vented to ambient. Pressurised nitrogen enriched air is released at the outlet of the membrane modules.

Case Sharing 1: Parker N2 membrane modules enhance the safety of under ground coal mines

Parker Hannifin China two OEM accounts: Aihua and Ruisai buying the below nitrogen modules and packaging their own nitrogen generator skids for reselling into coal mines.

· Module ST1508 x 238pcs

· Module SA1508 x 137pcs

Parker Hannifin China sold total 375pcs of 1508 modules and gained USD 1071K sales in FY11.

The use of nitrogen in those undergound coal mines is for fire prevention where 95%~97% nitrogen purity is applied to reduce oxygen concentration down to <10% and so as to:

· Inert worked-out or abandoned areas.

· Eliminate the risk of firedamp explosion.

· Prevent the coal from heating and self-ignite.

· Reduce burning intensity once fire occurs.

According to China regulations, equipmentto be used in gassy areas of coal mines must obtain a strict "Safety Certificate of Approval For Coal Mine Products". Such certificate must be applied by approved vendors that is far costly to qualify as. Thus, instead of selling the whole nitrogen skids directly to users, PH China sold nitrogen modules to those qualified OEM customers.

Features

· Lowest capital investment with same or smaller size ofair compressors as with competitive membranes.

· Significant air factor reduction on SMARTFLUX.

· Smallest membrane module in the world (N2 flow vsdimension of the module).

· Lowest compressed air pressure possible.

· Less membrane modules required per system / Small system footprint.

· Factory membrane ageing treatment pre-delivery.

Case Sharing 2: Chemical tank blanketing in Marine Industry China

Customer manufactured CO2 systems, but they switched to Nitrogen system with Parker memberanes due to easier system layout and operation (instant nitrogen on demand).

Features

· Utility of Membrane Modules: Chemical tank blanketing

· Industry: Marine Industry China

· Nitrogen pressure on demand: 8 barg

· Nitrogen float rate: 750m³/hr

· Nitrogen purity: 95%

· Nitrogen membrane module: 19 x ST1508

Originally, the customer manufactured carbon dioxide (CO₂) systems for industrial applications. These systems were designed to store, regulate, and distribute CO₂ gas for various processes, relying on high-pressure cylinders or bulk storage tanks.

Realizing many foreseeable limitations, the customer transitioned to nitrogen generation systems using Parker membrane technology. This shift offered significant advantages, particularly in terms of system simplicity and operational efficiency.

The reliability and low maintenance requirements of Parker's membranes further enhanced system uptime, making nitrogen generation a more sustainable and cost-effective long-term solution compared to traditional CO₂ systems.

Case Sharing 3: Apage Project, LNG/CNG container tank blanketing

In LNG (Liquefied Natural Gas) and CNG (Compressed Natural Gas) storage and transportation systems, nitrogen blanketing is a critical safety measure used to prevent flammable mixtures, maintain inert atmosphere, control pressure & purity. Compared to traditional methods, Parker nitrogen membrane module provides significant advantages in safety enhancing, costs lowering and scalability.

· Industry: LNG/CNG

· Nitrogen pressure: 9 barg

· Nitrogen float rate: 2160m³/hr

· Nitrogen purity: 95%

· Membrane module: 10x SA15020

Customers in Oil & Gas Industry

Parker membrane module customers include Oil & Gas industry leaders such as Shell, BP, ExxonMobil, Total, Petrobras, BHP, Weatherford, Hamworthy, and Royal Vopak.