Aluminum Alloy Liquid Nitrogen Container

SYDS Series - Biological Liquid Nitrogen Container

YDS Series are designed for the long-term storage of liquid nitrogen and samples. Featured with high-vacuum insulation aviation-grade aluminum alloy, these containers ensure minimol nitrogen evaporation and maximum eficiency. Their secure locking guarantee sample protection in labortory seting.

· Available with storage & transpotation

· Aviation grade aluminum

· Light-weigh, high strength & rust-free

· 3~175 liters, wide capacity range

· JODUN® paint, non-toxic guarantee

SYDS series are designed for long-term static cryogenic storage for biological samples at -196℃ tempearature. With high strength aluminum, multiple-layer vacuum insulation, high performance JOTUN® paint finish and CE certification, these contaienrs offer 50% higher protection of your samples with ultra low liquid nitrogen consumption.

Top Class Material

To ensure sample security at -196℃ temperature storage conditions, we use top brand materials and first-class manufaturing techniques to build liquid nitrogen containers for cryogenic storage.

1. Aviation-grade Aluminum Alloy

To guarantee structural integrity under cryogenic liquid nitrogen conditions, the vessel's shell is constructed entirely from high-strength, lightweight, and corrosion-resistant aviation-grade aluminum alloy, meeting stringent performance requirements for cryogenic liquid nitrogen containers.

High Strength-to-Weight Ratio: Maintains structural integrity while minimizing weight, critical for portable liquid nitrogen dewar.

Corrosion Resistance: Oxide layer (Al₂O₃) provides inherent resistance to oxidation and chemical degradation, safeguard to your samples.

Cryogenic Toughness: Retains ductility and resists brittleness even at ultra-low temperatures -196°C for liquid nitrogen shock.

2. JOTUN® Paint Finish

Globally renowned JOTUN® paints (from Norway) not only deliver exceptional gloss and texture but also ensure eco-friendliness, non-toxicity, and long-term durability for reliable performance.

Superior Durability & Protection: Heavy-duty formulations protect assets in harsh environments and abrasion resistance.

Eco-Friendly & Safe: Complies with EU REACH, GreenGuard Gold, and LEED standards, non-toxic guarantee.

Aesthetic Excellence: Dirt-repellent surfaces retain pristine finishes and advanced pigments resist fading.

Advanced Manufacturing Technology

1. Forward-Thinking Design

Rooted in innovation and future-ready solutions, our design approach combines cutting-edge technology, user-friendly operation, fine appearance while retain the cryogenic perforance.

Modern Aesthetics: Treamlined, minimalist silhouette, SYDS series combine futuristic appeal with functional elegance.

Design Meets Performance: Wide-neek for large-quantity storage, slope and narrow-neck for transporation, our design is beyond beauty.

Multi-Layer Shielding: Super insulation materials require precise spacing - YDS series structural alignment avoids thermal bridging.

2. Automated Material Processing

Automated material processing equipments eliminates human error in critical dimensions and reduces material waste by optimizing cutting path which provide competitive advantages in cost lowering.

CNC Machining Centers: High-precision cutting, drilling, and milling of aluminum alloy to exact tolerances (±0.1mm).

Laser Cutting Systems: Clean, burr-free edges for seamless welding.

Hydroforming Machines: Shape aluminum sheets into seamless cylindrical or spherical vessels without weak joints.

3. Robotic Welding & Assembly

Liquid nitrogen containers require leak-proof, high-strength, and cryogenically stable welds to maintain vacuum integrity and structural reliability. Robotic welding is the preferred method due to its precision, repeatability, and efficiency.

Higher Precision – Repeatable weld paths with ±0.05mm accuracy.

Faster Cycle Times – Robots weld 3–5x faster than humans.

Lower Defect Rates – Near-zero porosity/cracks which is critical for vacuum retention.

Safer Operations – No human exposure to cryogenic hazards or UV radiation.

4. High Standard Vacuum Insulation

Vacuum insulation is the core technology enabling liquid nitrogen (LN₂) containers to maintain -196°C ultra-low temperatures with minimal heat transfer.

Multi-Layer Insulation: Multiple alternating layers of aluminized Mylar + fiberglass spacer achieve <0.1% daily evaporation.

High-Vacuum Sealing: Long-lasting evacuate air to 10⁻³ – 10⁻⁶ Pa and then seal using electron beam welding to prevent leaks.

Helium Mass Spectrometry Testing: Testing every product with automatic process ensures <10⁻⁹ mbar·L/s leak rate.

5. Quality Control & Testing Automation

To ensure safety, durability, and thermal performance, SYDS series undergo rigorous quality control QC and testing before labeling and packing.

AI-Powered Vision Inspection: Detects micro-cracks, porosity, or misalignments.

Helium Mass Spectrometers: Automated leak testing with sensitivity of 10⁻⁹ mbar·L/s.

Cryogenic Shock Testers: Subjects containers to rapid -196°C cycles to validate durability.

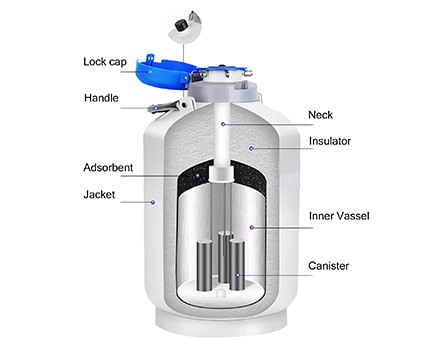

Product Features

SYDS series liquid nitrogen containers, made of high-strength aluminum alloy with multiple layers vacuum insulation design to minimize heat conduction, are the ideal application for long term static cryogenic storage and long distance transpotation of biological samples.

1. Liquid Nitrogen Containers for Sample Preservation

Liquid nitrogen containers of this type are chosen to preserve samples or liquid nitrogen indoors for long time under static conditions, featured typically with low static evaporation rate and low maintenance cost.

3~175L Volume

Various of models for wide range of application senarios.

Wide Neck

Wide neck for easy storage and take out of sampels.

Lifting Racks

Multiple layers of lifting racks made of SUS304 stainless steel.

Safty Locker

Safety concerns as well as for lower evaporation rate.

| Model | Volume | Outer Diameter (mm) | Opening Size (mm) | Height

(mm) | Weight(kg) | Evaporation Rate (L/day) | Static Retation Period (day) |

| SYDS-3 | 3 | 244 | 50 | 401 | 3.9 | 0.12 | 26 |

| SYDS-5-200 | 5 | 304 | 200 | 373 | 4.9 | 1.67 | 3 |

| SYDS-6 | 6 | 304 | 50 | 429 | 5.2 | 0.12 | 52 |

SYDS-10 | 10 | 304 | 50 | 541 | 6.6 | 0.12 | 86 |

SYDS-10-80 | 10 | 304 | 80 | 540 | 6.7 | 0.21 | 48 |

SYDS-13 | 13 | 318 | 50 | 595 | 7.2 | 0.12 | 109 |

SYDS-13-127 | 13 | 318 | 127 | 590 | 8.0 | 0.50 | 26 |

SYDS-15 | 15 | 379 | 50 | 565 | 9.2 | 0.12 | 134 |

SYDS-15-127 | 15 | 379 | 127 | 555 | 9.3 | 0.44 | 36 |

SYDS-20 | 20 | 379 | 50 | 650 | 10.6 | 0.12 | 168 |

SYDS-30 | 30 | 449 | 50 | 698 | 13.8 | 0.12 | 254 |

SYDS-30-80 | 30 | 449 | 80 | 707 | 14.3 | 0.21 | 147 |

SYDS-30-127 | 30 | 449 | 127 | 730 | 14.6 | 0.38 | 83 |

SYDS-30-200 | 30 | 449 | 200 | 705 | 15.5 | 0.68 | 46 |

SYDS-35 | 35 | 449 | 50 | 708 | 14.3 | 0.12 | 286 |

SYDS-35-80 | 35 | 449 | 80 | 717 | 15.5 | 0.22 | 159 |

SYDS-35-127 | 35 | 449 | 127 | 722 | 14.3 | 0.38 | 93 |

SYDS-35-200 | 35 | 449 | 200 | 725 | 14.4 | 0.38 | 52 |

SYDS-47-127 | 47 | 522 | 127 | 730 | 22 | 0.45 | 105 |

SYDS-65-216 | 65 | 592 | 216 | 772 | 34.4 | 0.89 | 73 |

SYDS-120-216 | 120 | 592 | 216 | 1046 | 43.8 | 0.95 | 127 |

SYDS-175-216 | 175 | 691 | 216 | 1083 | 55.2 | 0.95 | 184 |

2. Liquid Nitrogen Containers for Sample Transportation

SYDS-B series are suitable for biological sample transport over long distance. Featuring with side-support structure at inner dewar to advoid impact of shaking to the internal liquid nitrogen, the containers can effectively ensure safety of the samples.

30~100L Option

30~100 liters volume to satisfy various needs of sample transport

Long-Narrow Caliber

Long & narrow neck, slope side structure for sample safety

Inner Structure

Multiple layers insulation to ensure minimal liquid nitrogen consumption

Canisters

Made of food-grade stainless steel to ensure strength at mobility

| Model | Volume | Outer Diameter (mm) | Opening Size (mm) | Height

(mm) | Weight(kg) | Evaporation Rate (L/day) | Static Retation Period (day) |

SYDS-20B | 20 | 379 | 50 | 650 | 10.6 | 0.2 | 101 |

SYDS-30B | 31.5 | 449 | 50 | 698 | 14.1 | 0.2 | 159 |

SYDS-35B | 35.5 | 449 | 50 | 708 | 14.3 | 0.2 | 179 |

SYDS-50B | 50 | 522 | 50 | 770 | 22.8 | 0.24 | 209 |

SYDS-30B-80 | 31.5 | 449 | 80 | 707 | 14.3 | 0.30 | 106 |

SYDS-35B-80 | 35.5 | 449 | 80 | 717 | 14.6 | 0.30 | 119 |

SYDS-35B-127 | 35.5 | 449 | 127 | 722 | 15.7 | 0.43 | 82 |

SYDS-50B-80 | 50 | 522 | 80 | 770 | 23.2 | 0.34 | 147 |

SYDS-50B-127 | 50 | 522 | 127 | 779 | 23.8 | 0.48 | 105 |

SYDS-50B-200 | 50 | 522 | 200 | 773 | 24.0 | 0.74 | 68 |

SYDS-100B-127 | 100 | 592 | 127 | 929 | 39.7 | 0.48 | 210 |

SYDS-100B-200 | 100 | 592 | 200 | 929 | 38.9 | 0.76 | 131 |

10 results

ViewShowcase

SYDS series liquid nitrogen containers are specially designed for long-term storage of biological samples

SYDS-120-216 liquid nitrogen tank is suitable for biomedical, stem cell mass storage with small occupied space and low liquid nitrogen consumption rate.

SYDS series liquid nitrogen containers are specially designed for long-term storage of biological samples

SYDS series liquid nitrogen containers are specially designed for long-term storage of biological samples

SYDS-47-127 is a cryogenic storage solution with 47l capacity and low LN2 consumption comes with 6 canisters.

SYDS series liquid nitrogen containers are specially designed for the long-term storage of biological samples

SYDS series liquid nitrogen containers are specially designed for the storage of biological samples requiring long-term storage

SYDS series liquid nitrogen containers are specially designed for the storage of biological samples requiring long-term storage

SYDS series liquid nitrogen containers are specially designed for storage of biological samples requiring long-term storage.

SYDS series liquid nitrogen containers are specially designed for the storage of biological samples requiring long-term storage