Nitrogen Generator

On-Site Nitrogen Generators

Generate nitrogen on-demand, not on-delivery. Our industrial nitrogen generators enable in-house production of nitrogen at your specified purity level. Reclaim control over supply chains, minimize waste, and guarantee 24/7 operational readiness.

· 95%~99.999% Purity

· All-in-one Design, Plug and Play

· Patented Controller & High Reliability

· One-click Operation, Fully Automatic Running

Introduction

A nitrogen generator is an on-site gas production system that extracts nitrogen gas (N₂) directly from compressed air, eliminating the need for third-party nitrogen deliveries (cylinders or liquid dewars). It uses air separation technology to isolate nitrogen molecules from other atmospheric gases.

As an original manufacturer, we deliver customers all over the world nitrogen generators with purity up to 95%-99.999% serving various industries. Scala nitorgen generators range from desktop generators to all-in-one model and nitrogen generators with gas containers, with nitrogen flow rate from 1Nm³/hr to 2000Nm³/hr.

Our team - comprised of seasoned industry veterans, dynamic mid-career experts, and emerging young talent - drives the continuous development of next-generation nitrogen generation systems.

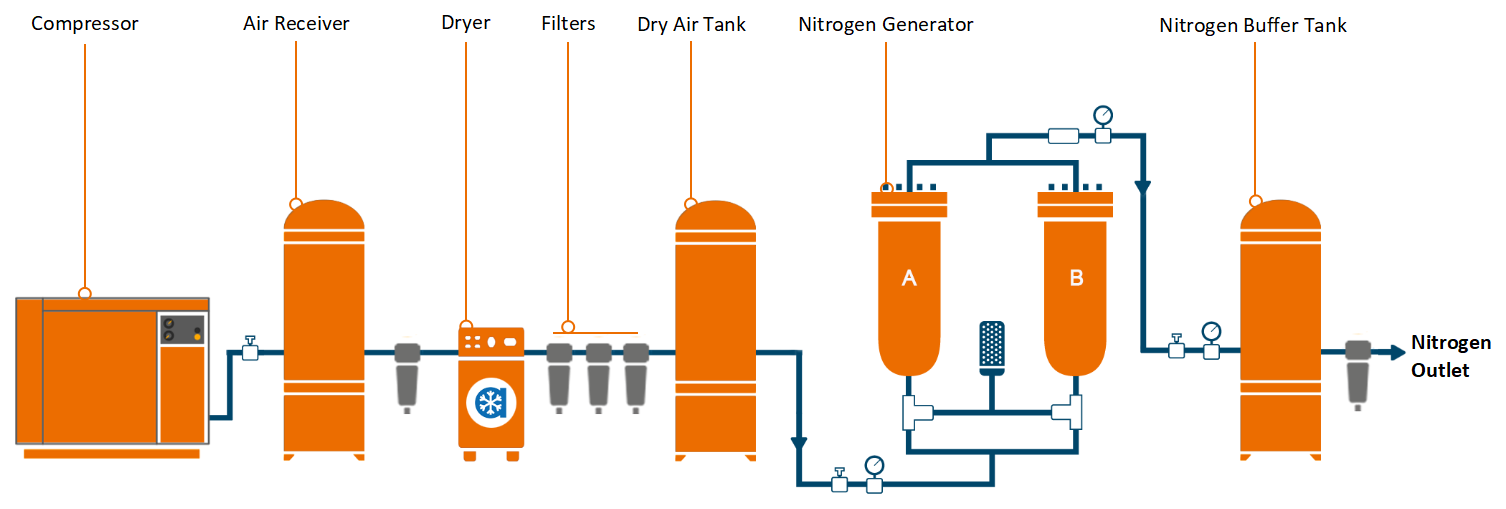

Flow Chart of Nitrogen Generation

Typically, nitrogen generation requires equipments as blow.

1. Air Compressor

· Function: Provides compressed air (typically at 7-10 bar) as the feed gas for nitrogen generation.

· Types: Oil-injected or oil-free screw compressors, depending on purity requirements.

2. Air Receiver Tank (Buffer Tank)

· Function: Stores compressed air to ensure a steady supply, reducing pressure fluctuations and acting as a buffer.

3. Air Dryer (Refrigerant or Desiccant)

· Function: Removes moisture from compressed air to prevent condensation, which can damage downstream equipment.

· Types:

Refrigerant Dryer: Cools air to remove water.

Desiccant Dryer: Uses adsorbent materials (e.g., silica gel) for very dry air (needed for high-purity nitrogen).

4. Particulate Filters (Pre-Filtration)

· Function: Removes oil aerosols, dust, and solid particles from the compressed air before it enters the nitrogen generator.

· Common Types:

Coalescing Filter: Removes oil and water droplets.

Activated Carbon Filter: Adsorbs oil vapors and odor.

5. Nitrogen Generator

Scala provide customers with both dual-tower PSA nitrogen generators and modular nitrogen generators, which can continuously producing nitrogen at apressure of 0.7-1.3Mpa with purity 95%~99.999%, capacity ranges from 1Nm³ per hour to 2000Nm³ per hour.

On-site Nitrogen Generation vs Nitrogen Bottle Deliver

On-site nitrogen generator is an excellent long-term choice for high-volume / continuous nitrogen users and a perfect replacement for nitrogen bottles. Bulky nitrogen cylinders wastes space and there would be potential risks to handle the high pressure equipments. On-site nitrogen generation redeces waste and offer on-demand purity with 24/7 continous supply.

Bottled N2 Supply

· Complex opeartion, a pressure reducing valve and control system are needed.

· Ever-present safety risk, heavy vessels containing gas under high pressure.

· Rental/delivery problems, you may forget to order, delivery delay, storage spaces, etc.

· Routine work trouble, you may need order, arrange payment and a lot of checkings.

· Higher cost, regular consumer of nitrogen rely on bottled nitrogen gas may be very costly in the long run.

On site N2 Generation

· Safe and fast, saves you the trouble of handling or purchasing, etc.

· Pressure controllable, continuous nitrogen gas production without interruption.

· Easy to use, plug and play, fully automatic running, saves pernel on duty.

· Portable, flexible and convenient, eliminates the hassle of transportation..

· Cost effective, only electricity consumption cost which will save you lots of money for one-time investment.

4 results

ViewShowcase

Scala NG series nitrogen generators are scalable, flexible systems designed to produce high-purity nitrogen on-site, with the ability to expand capacity as needed.

SMN membrane nitrogen generators enable customer to acquire nitrogen gas easily from the air with proven membrane separation technology, ideal for low (90%) to medium (99.5%) purity applications.

SPN1001/2D are mini all-in-one portable nitrogen generators designed for customers without compressed air equipment, supplying 130~1000L/hr nitrogen with 95% ~ 99.5% purity.

Scala HN4 series nitrogen generators are designed for large volume high purity nitrogen gas supply with 95%~99.999% purity.

Application of Nitrogen

As an inert, colorless, odorless gas, nitrogen is widely used in diverse applications across multiple industries due to its non-reactive properties, ability to displace oxygen, and cooling capabilities when liquefided.

Food & Beverage

Packaging

Pharmaceutical

Drug Manufacturing

Semiconductor

Chip Making

Oil & Gas

LNG

Coal Mining

Blanketing

Chemical

Petrochemical

Grain

Grain Storage

Electronics

Laser Cutting

1. Food & Beverage Industry

· Modified Atmosphere Packaging (MAP): Replaces oxygen to extend shelf life (prevents oxidation and spoilage).

· Blanketing: Protects wines, oils, and juices from oxidation during storage and bottling.

· Freezing & Chilling: Used in cryogenic freezing (liquid nitrogen at -196°C) for quick freezing (e.g., seafood, meat, vegetables).

· Beer & Soft Drink Dispensing: Provides pressure for kegs without altering taste.

2. Pharmaceutical & Healthcare

· Drug Manufacturing: Prevents oxidation in sensitive chemical processes.

· Blanketing: Protects vaccines, medicines, and biologics from contamination.

· Medical Gas Mixtures: Used in respiratory therapies (mixed with oxygen).

· Cryopreservation: Freezes and stores biological samples (sperm, eggs, stem cells).

3. Electronics & Semiconductor Manufacturing

· Soldering & Reflow Ovens: Prevents oxidation during PCB assembly.

· Wafer Fabrication: Creates inert atmospheres in cleanrooms.

· Laser Cutting: Used as an assist gas for precision cutting.

4. Oil & Gas (Petrochemical Industry)

· Well Stimulation (Nitrogen Fracking): Enhances oil recovery by pressurizing wells.

· Pipeline Purging: Removes flammable gases before maintenance.

· Tank Blanketing: Prevents explosions in storage tanks by displacing oxygen.

5. Chemical & Plastic Manufacturing

· Inerting: Prevents explosions in reactors handling volatile chemicals.

· Polymer Production: Used in extrusion and injection molding to prevent oxidation.

· Ammonia Synthesis: Key feedstock for fertilizers (Haber-Bosch process).

6. Laboratory & Research

· Gas Chromatography (GC): Carrier gas for analytical instruments.

· Cryogenics: Used in superconductors and MRI cooling.

7. Environmental & Wastewater Treatment

· Wastewater Denitrification: Helps remove nitrates from water.

· Soil Remediation: Assists in vapor extraction of contaminants.

8. Others

Metal Processing & Heat Treatment

Fire Prevention & Safety

Glass & Ceramics Manufacturing

3D Printing (Additive Manufacturing)

Etc.