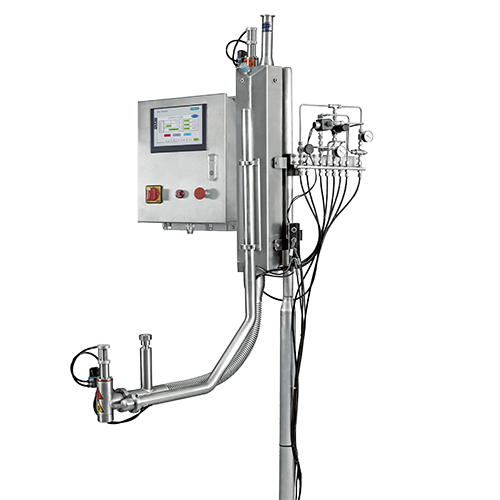

Liquid Nitrogen Doser

Liquid Nitrogen Dosing Machine

SVBS Series liquid nitrogen dosing machine quick and precise packaging solution for a wide range of products for preservation, pressurization and freezing.

· Third Generation LN2 Doser

· High Reliable PLC Controller

· Cutting Edge Cryogenics Technology

· Auto Speed Adjustment

· Precision Dosing & Speed Sync

The liquid nitrogen doser revolutionizes packaging by creating a pressurized, inert environment inside containers. It is designed for a wide range of "calm" food and beverage products—including oils, water, juices, wine, beer, low-alcohol beverages, ketchup, nuts, potato chips, and bread crumbs. This technology is compatible with various container types, such as aluminum cans, glass bottles, PET, and other plastic packaging materials.

SVBS Series are multi-purpose liquid nitrogen (LN2) dosing system utilizing advanced cryogenic technology and PLC programming for product package. Scala engineers designed ultra-efficient systems for low to medium production line speeds to dispense precise drops of liquid nitrogen into every bottle every time, significantly extends the product's shelf life by preventing oxidation.

Working Principle

Packing with liquid nitrogen doser leverages a simple physical phenomenon: when a drop of liquid nitrogen is injected into a container, it instantly vaporizes and expands in volume by 700 times. This expansion achieves two critical functions:

Creates an Inert Atmosphere: Before sealing, the vaporizing nitrogen expels residual air and oxygen from the container. Replacing oxygen with inert nitrogen gas significantly extends the product's shelf life by preventing oxidation. Documented studies show a 26% increase in shelf life and 90 to 95% reduction in headspace oxygen compared to traditional gaseous nitrogen purging.

Generates Internal Pressure: After sealing, the continued vaporization of the liquid nitrogen builds internal pressure. This pressure greatly enhances the rigidity and strength of aluminum, PET, and other plastic containers, which is essential for safe stacking, storage, and transport.

Additionally, this pressure prevents the "vacuum collapse" effect that can occur when hot-filled products cool down in a sealed container.

Benefits

An exact dose of liquid nitrogen is introduced seconds before the seamer or capper. The volumetric expansion of the vaporized nitrogen pushes oxygen out of the container.

Enhances Product Quality: By displacing oxygen inside the headspace of the container, nitrogen gas prevents oxidation (rancidity) and spoilage. This preserves the product's flavor, aroma, color, and nutritional value.

Extends Shelf Life: Significantly reduces the rate of product degradation, allowing for longer distribution cycles and reducing waste from expired goods.

Increases Container Rigidity: The internal pressure generated by vaporizing nitrogen gives plastic (PET) and aluminum containers exceptional strength and rigidity.

Packaging Versatility: Liquid nitrogen doser makes it feasible to package a wider range of products (both cold and hot-filled) in lightweight, cost-effective PET plastic instead of heavier glass or more expensive materials.

Features

Liquid nitrogen is supplied to the doser by a standard 10ft (3mt) vacuum insulated liquid nitrogen hose (various lengths available) and flows into the dosing head. A 24vdc PNP sensor detects the speed of the line (encoder compatible for higher speeds); a second 24vdc PNP sensor detects the presence of a container. When a container is detected, the dosing head opens and dispenses an exact amount of pure liquid nitrogen.

· Compact Size – enables installation in limited spaces.

· Precise Dosing – delivers consistent, accurate dosing.

· Discrete Dosing – up to 500 containers per minute (controller dependant).

· Discreteor Continuous Dosing – change over defined by user.

· Vacuum Insulated Technology – the most efficient use of LN2.

· Soft Dose Compatible – Scala's proven technology for hotfill, powder, and granular applications.

2 results

ViewShowcase

The SVBS - 300 is a 3rd generation cutting-edge liquid nitrogen (LN2) dosing system utilizing advanced cryogenic technology and PLC programming.

The SVBS - 200 is a multi-purpose liquid nitrogen (LN2) dosing system utilizing advanced cryogenic technology and PLC programming.