Vacuum Insulated Cryogenic Lines

Introduction

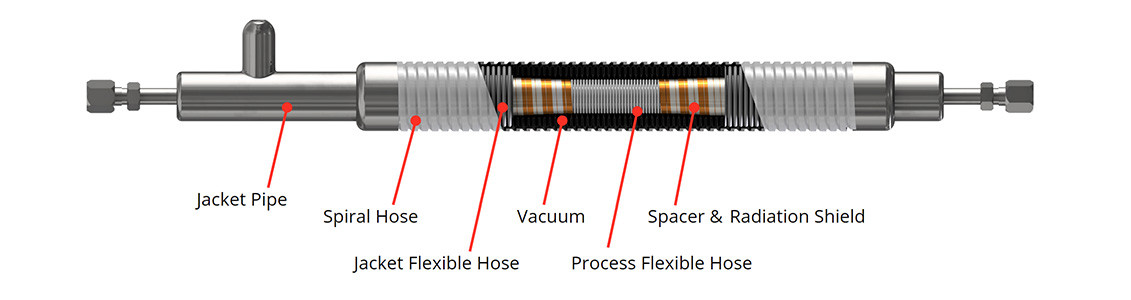

The static vacuum insulated hose is manufactured from 304 stainless steel, evacuated to a high vacuum of 10-6 mbar (10-4 Pa) with a vacuum pump. The hose is in modular structure and is assembled and connected with vacuum genderless blade connectors.

The hose is available in 3 standard inner diameter sizes: 0.394" (Model DN10), 0.625" (Model DN15) and 1.25" (Model DN25). The outer layer is protected by a flexible stainless steel braided sheath.

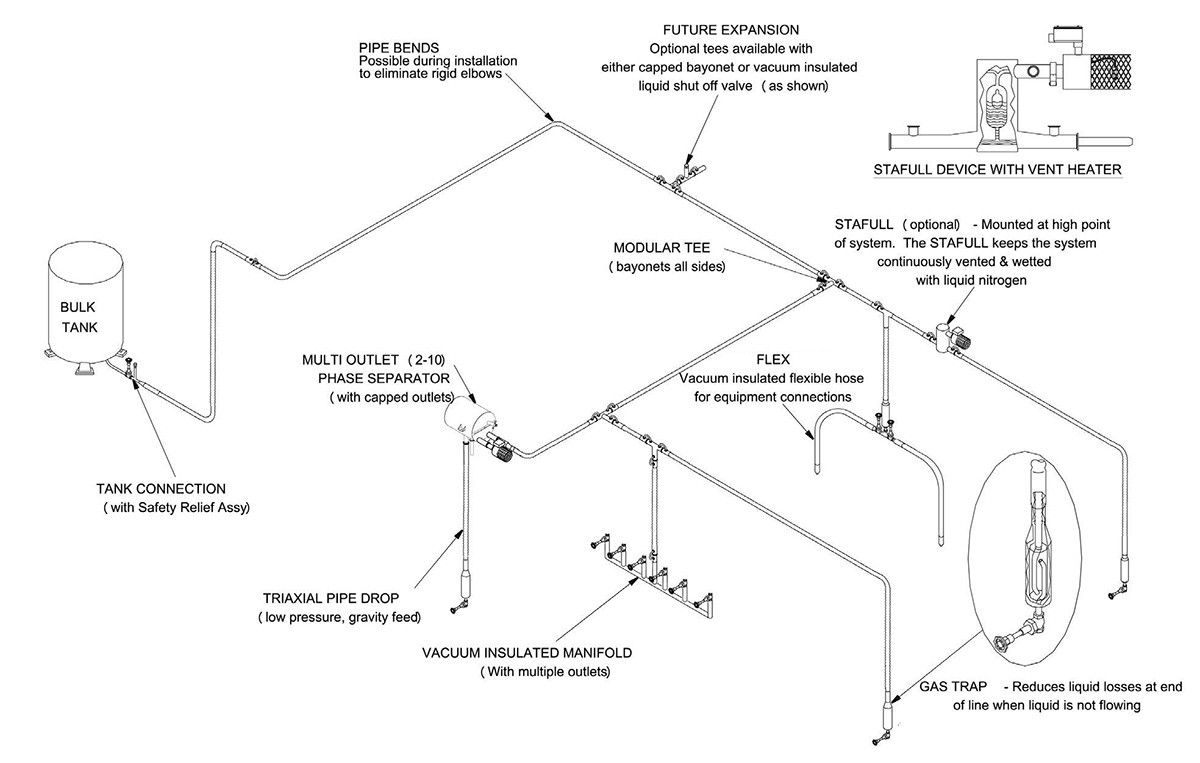

Scala provides a complete range of components, including inline exhaust devices, phase separators, gas traps, vacuum tees, and vacuum elbows, to maximize system performance and design flexibility.

Features

Highest Quality Standards in Cryogenics Industry

Space-saving – Eliminate on-site vacuum pumps, thus reduce pump maintenance and operational costs.

1-year vacuum warranty – Includes a 1-year warranty covering material and manufacturing defects.

Ultra-low heat loss – Lightweight stainless steel construction minimizes liquid nitrogen consumption.

Vacuum blade connections – Reduces liquid nitrogen leakage.

Modular design – Enables easier maintenance, flexible pipeline adjustments and system expansions.

· Applicable: LO2、LN2、LAr、LH2

· Temperature: -196 ℃ (-320°F)

· Max Pressure: 3.2 MPa

· Material: SUS304

· Condition: New

· Warranty: 1 Year

Outer Jacket

Made of light weight 304 stainless stell

Connect Diagram

Modular structure for easy assemble and connection

Bayonet Connection

Female and male connectors with clamp

3 results

ViewShowcase

Beverage Industry Spiral Wrap Liquid Nitrogen Vacuum Jacketed Transfer Hose Designed for Long Time Service and Flexiable Connections.

Scala offers a number of different types of cryogenic transfer hoses. This particular piece of equipment is an indispensable accessory for the safe and efficient transfer of liquid cryogens

Scala offers a number of different types of cryogenic transfer hoses. This particular piece of equipment is an indispensable accessory for the safe and efficient transfer of liquid cryogens

Manufacturing Process & Quality Assurance

Scala factory conduct highest manufacturing stands and strictest qulilty inspections before package and delivery to ensure best quality for cryogenic applications.

Vacuum Pumping

Leakage Detection

Liquid Nitrogen Shock

Nitrogen Gas Purge

Benifits

+ Outer flex section remains ambiet - no personnel hazard, safe to touch.

+ Super insulated vacuum lines - ensure the highest quality liquid cryogen is delivered to the

use point.

+ Improved Productivity - reduced cooling time and faster delivery of liquid cryogen to the

use point, due to rapid hose cool down.

+ Lower Cryogen Consumption - save money.

+ Finish - All ends are polished to a high luster finish.

+ Lighted weigh SS304 - fabricated from 304 Stainless Steel with a highly flexible outer spiral wrap + superflex braid.

+ Connection convenience - can be combined with plant piping systems to provide efficient connections to usepoint.

+ Modular structure - can be supplied in kit form for installation by local labour.

+ QC - every hose is leak tested and cold shocked to ensure its vacuum integrity.

+ High vacuum - each hose is sealed under vacuum with a combination seal.

+ Easy handle - small outer diameter and light-weigh in comparison to equivalent lagged lines.

Standard Installation Diagram