Scala Stainless Steel Vacuum LN2 Transfer Hose Delivered to Middle East Beverage Producer

Abstract

Designed specifically for liquid nitrogen transfer systems in the beverage industry, these hoses feature ultra-vacuum insulation, low nitrogen loss, and a frost-free exterior. Prior to delivery, the products underwent rigorous helium leak testing and liquid nitrogen shock tests. The built-in filtration rod removes impurities from the liquid nitrogen, ensuring food-safe transfer.

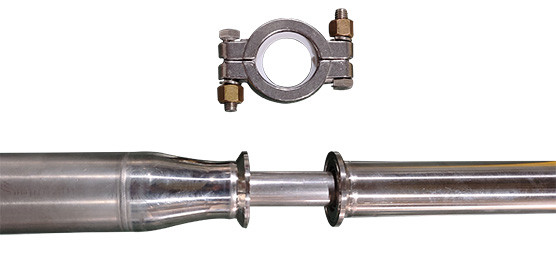

With an innovative modular snap-fit connection system, the hoses can be extended indefinitely, making them perfectly suited for modern beverage production lines.

Hangzhou China

Liquid Nitrogen Transfer Solution for the Beverage Industry

The diameter of the liquid nitrogen delivery pipeline is DN15, including two length combinations of 4 meters and 7 meters, which can be flexibly arranged in different workstations such as filling lines and packaging lines.

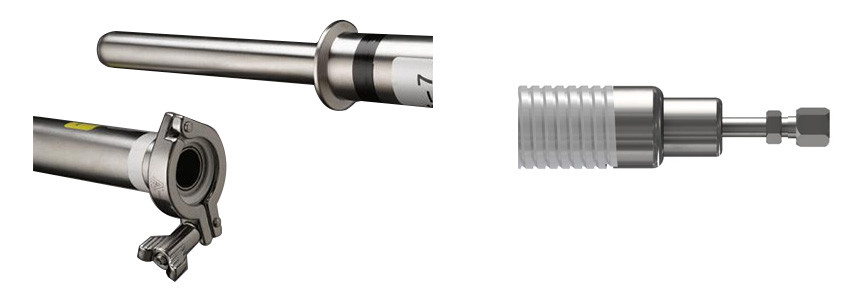

The hoses interface, NPT 1/2 Female thread and M-F head buckle design, not only ensure the sealing of the pipeline, but also realize rapid disassembly and assembly, greatly improving the efficiency of production line maintenance.

Technological Innovation Ensures Production Efficiency

Ultra-vacuum insulation technology: effectively control the evaporation rate of liquid nitrogen and reduce the loss to the lowest level in the industry;

Anti-frost design: ensure the dryness of the outer jecket of the pipeline to avoid condensed water from polluting the production environment;

Built-in filtration system: high performance filter rods can intercept tiny particles to ensure the purity of injected liquid nitrogen.

All products undergo strict helium mass spectrometry leak detection tests and liquid nitrogen impact tests before package to ensure vacuum performance meets aerospace grade standards. Its modular snap-on connection system supports unlimited extension and can be flexibly adjusted with the expansion of the production line, saving customers a lot of modification costs.

Boosting the Middle East Beverage Industry Upgrade

The high-temperature climate in the Middle East poses a severe challenge to beverage preservation, and liquid nitrogen dosing technology has become an industry standard. The vacuum liquid nitrogen transfer hose solution provided by Scala can significantly reduce liquid nitrogen consumption, helping customers achieve cost reduction and efficiency improvement.

It is informed that the hoses will be applied in the liquid nitrogen dosing stage of PET beverages bottling to extend product shelf life. In the future, Scala plans to collaborate with more international food companies to promote innovative applications of liquid nitrogen in areas such as dairy products and juice.

The air freight delivery is a showcase of the quick response to global customer demands. Scala will continue to invest in research and development to provide the food and beverage industry with smarter and more energy-efficient cryogenic fluids transfer solutions.