LSN10A Liquid Nitrogen Generator Update: Better Operating Experience and More Reliability

The recent updates to the LSN10A Liquid Nitrogen Generator include two key improvements aimed at enhancing operational convenience and long-term stability during use. These optimizations significantly increase the practical value of the equipment.

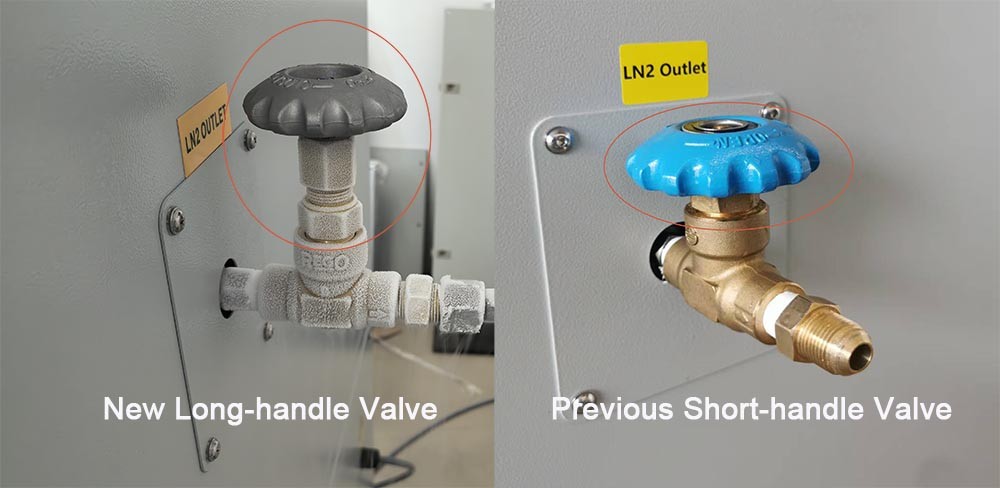

1. Emergency Globe Valve Upgrade: Eliminating Troubles from Cryogenic Freezing

LNS10A was previously equipped with a short-handle emergency globe valve. After liquid nitrogen dispensing, the valve was prone to freezing due to ultra low temperature. This would cause users have to wait 15 to 20 minutes for the valve to thaw before operating it again, which not only reduced work efficiency but also risked delaying critical responses in emergencies.

With this improvement by replacing the short-handle valve with a long-handle REGO cryogenic globe valve. As a specialized brand in low-temperature valves, REGO offers products with superior stability in cryogenic environments. The long-handle design reduces heat transfer to the operating components, effectively preventing valve from freezing. Users can operate the valve immediately without waiting for thawing with this improvement, significantly enhancing both continuous operational capability and emergency response efficiency.

2. Vacuum Insulation Hose Upgrade: Lightweight Design Enhances Durability

Vacuum-insulated hose is a divice used to transfer liquid nitrogen safely from the generator to external equipment. Previously we provide customers with a braided mesh outer layer vacuum hose with LNS10A. While this design met basic thermal insulation requirements, it presented two major issues: Firstly, the pipes were relatively heavy and had a large bending radius, making them difficult to maneuver in tight room or when flexible routing adjustments were needed. Secondly, after prolonged use (approximately 1-2 years), the connection points between the braided mesh and the fittings were prone to detachment, compromising both thermal insulation performance and equipment safety.

The upgraded vacuum insulated hose now features lightweight SS304 stainless steel. These new hoses are not only significantly lighter but also have a smaller bending radius, allowing for easier and more flexible layout adaptation in various practical scenarios. Additionally, the connection technology at the interfaces has been optimized to reduce the risk of detachment over long-term use. This improvement extends the service life of the hoses and lowers maintenance costs.

These two upgrades directly address the practical pain points of the LSN10A Liquid Nitrogen Generator. By enhancing both operational convenience and equipment durability, the improvements significantly boost the product's performance - better meeting the demand for efficient and stable operation of liquid nitrogen equipment in fields such as scientific research and healthcare.